Scraper wrinkling—frequent questions from papermaking companies

Release time:

2024-06-12

“Tissue” is commonly used to refer to toilet paper, but in fact, “tissue” refers to a whole category of paper. Therefore, it’s sometimes also written as “tissue grades.”

“Tissue” is commonly used to refer to toilet paper, but in fact, “tissue” refers to a whole category of paper. Therefore, it’s sometimes also written as “tissue grades.”

Tissue grades are generally referred to as thin paper. Hygiene products include facial tissues, napkins, toilet paper, and other similar items. There are also some industrial-grade thin papers, such as carbon copy paper, packaging paper, and capacitor paper.

Because this type of paper has a very low basis weight and a loose structure, thin papers are generally not produced on conventional paper machines.

Thin paper machines come in a variety of designs, typically featuring a long-wire forming section combined with a Yankee dryer cylinder. A key characteristic of all thin paper machines is that the paper web is supported throughout the entire forming, pressing, and drying processes—no tension is applied to the paper until the drying stage is complete.

For thin papers with lower basis weights, a lick-up felt is sometimes used to transfer the paper web from the forming section to the press section (replacing the vacuum suction roll). The lick-up felt is relatively impermeable and operates in a wet state. The felt adheres closely to the wire mesh, allowing the paper web to adhere preferentially to the felt.

The Yankee dryer is a large-diameter drying cylinder serving as the primary drying device. The wet paper sheet is tightly pressed against the highly polished surface of the dryer and transferred onto its surface. The Yankee cylinder is enclosed by an air hood and can be equipped with high-speed air jets to enhance its drying capacity. Some Yankee cylinders can apply a single-sided finish to the paper sheet; these cylinders are also referred to as M.G. dryers (machine-glazed). Such dryers can also be used for finishing cardboard and for cast-coating applications.

Before being rolled into paper rolls, the paper sheets may or may not undergo calendering, depending on the paper grade. Some paper machines are even equipped without calenders at all; for certain grades, calendering is performed externally using a super-calender.

The first commercially available thin-paper web-forming machine was the crescent former, developed by Kimbely-Clark in the 1960s.

For the production of toilet paper, the wrinkling caused by the doctor blade is a crucial step. How to better ensure the quality of the paper is a key concern for paper manufacturers.

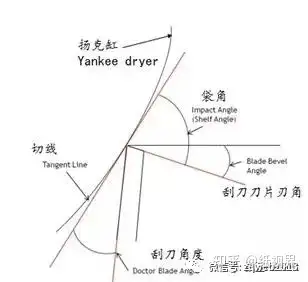

In normal production, the function of the creping blade is to peel off the tissue paper adhering to the surface of the drying cylinder and to create crepes by utilizing a certain speed differential between the winding cylinder and the Yankee cylinder.

The quality of the blade material, the magnitude of the blade loading angle (blade angle), the variation in the angle between the blade edge and the tangent to the cylinder surface (bag angle), and the contact position of the blade edge on the cylinder surface—all these factors significantly influence the physical and aesthetic properties of toilet paper, such as the fineness and fullness of its wrinkles and its tensile strength.

The above are the key points to keep in mind when designing and adjusting doctor blades. In addition, wrinkled doctor blades are essential and consumable items in the production of household paper. As China’s papermaking industry continues to expand, the market demand for these blades is steadily increasing.

What should we pay attention to when selecting scraper blades?

Tips for Selecting Materials for Wrinkle-Resistant Blades

Choosing the right blade material for wrinkling in Yankee cylinders is crucial.

The material selection ranges from steel blades and long-life alloy blades to thermally sprayed ceramic blades.

Factors to consider when selecting material for corrugated blades include:

— Target blade performance — Yankee cylinder chemical coating — Yankee cylinder surface condition — Paper product quality requirements

It is recommended to consult a Yank cylinder scraper expert to determine the most suitable wrinkling scraper blade application for your needs.

Under the development trend of spraying metallic materials onto the surface of Yankee dryer cylinders, new type of corrugated doctor blades—particularly ceramic doctor blades—have been clearly recognized as significantly extending blade service life and enhancing the softness of tissue paper sheets.

Hengfengli corrugated blades are the best choice for improving the productivity of tissue paper machines.

Source: Zhishi.com

Keywords:

Previous page

Previous page:

Liuzhou Hengfengli Knives Co., Ltd.

National Sales Hotline:

LLiuzhou Hengfengli Knives Co., Ltd.

Address: No. 1 Xingfu Road, Xinxing Industrial Park, Liuzhou City

Contact phone number:13977213603

Mobile official website

Copyright © 2024 Liuzhou Hengfengli Knives Co., Ltd.